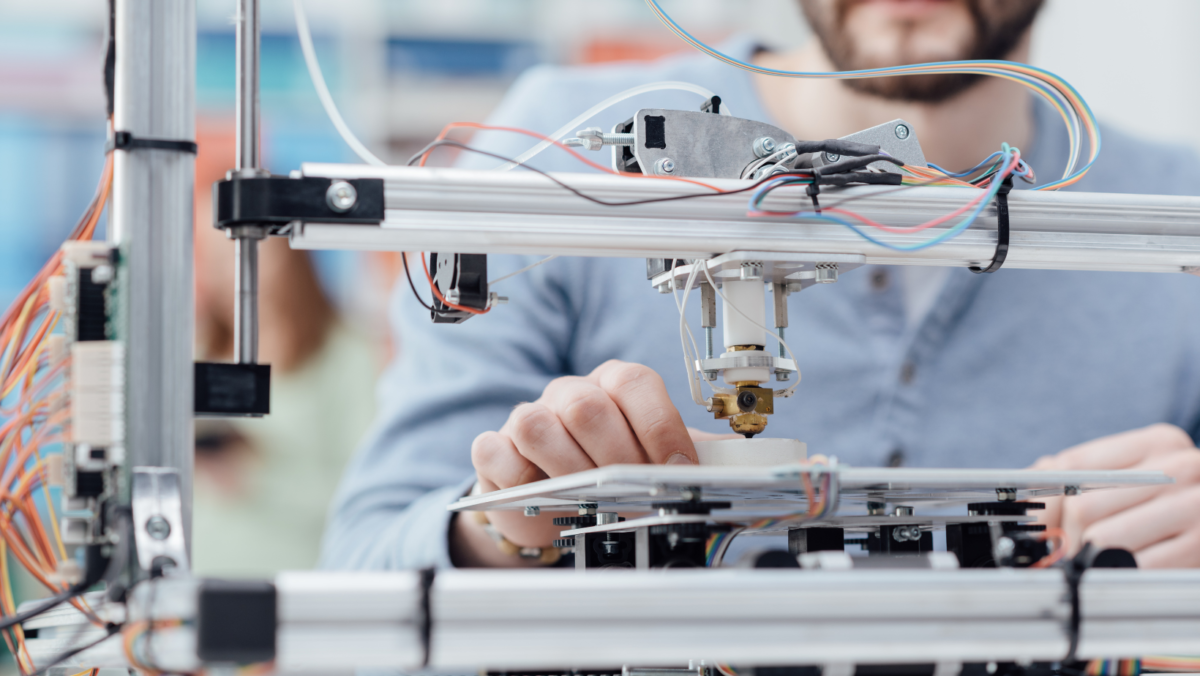

The Role of 3D Printing in Designing Custom Spinal Disc Implants

Advancements in medical technology have revolutionized spinal care, and 3D printing stands at the forefront of these innovations. Dr. Larry Davidson, a leader in spinal surgery, recognizes that custom spinal disc implants, designed through 3D printing, offer a tailored approach to treating conditions like degenerative disc disease and spinal injuries. Unlike traditional implants, these custom designs align closely with a patient’s unique anatomy, promising better outcomes and improved functionality. The integration of 3D printing technology in spinal surgery reflects a significant leap in precision and personalization.

Understanding 3D Printing in Medical Applications

3D printing, or additive manufacturing, is a process of creating three-dimensional objects layer by layer from digital designs. In the medical field, it enables the production of implants and prosthetics that are customized to an individual’s anatomy. For spinal disc implants, this means producing devices that precisely match the patient’s spinal structure, ensuring a more natural fit and better integration.

Traditional spinal implants are often designed with standard shapes and sizes, which may not align perfectly with every patient’s anatomy. Custom 3D-printed implants, however, are created based on detailed imaging data, such as CT or MRI scans. This allows surgeons to address specific spinal issues with implants that are optimized for everyone.

Benefits of Custom 3D-Printed Spinal Disc Implants

The application of 3D printing in spinal surgery offers several advantages over traditional implant designs. One of the primary benefits is the level of precision it enables. Custom implants are designed to fit the unique contours of a patient’s spine, reducing the risk of complications such as implant migration or improper alignment.

Another significant advantage is improved functionality. Because 3D-printed implants mimic the natural anatomy of the spine, they help preserve motion and distribute forces more evenly. This reduces strain on adjacent segments, potentially lowering the risk of Adjacent Segment Disease (ASD). Patients often experience better pain relief and a quicker return to mobility compared to those with standard implants.

Additionally, 3D printing allows for innovative material combinations that improve implant durability and biocompatibility. For instance, porous structures can be designed to encourage bone ingrowth, enhancing the implant’s stability over time. These materials are also lightweight, which minimizes stress on surrounding tissues.

Challenges in Implementing 3D Printing for Spinal Implants

While 3D printing has revolutionized spinal care, challenges remain. High costs of technology and materials can burden patients and providers. Custom implants also face rigorous regulatory processes, delaying availability. Additionally, integrating 3D printing into surgical workflows requires collaboration among specialists, complicating planning. However, ongoing advancements are steadily addressing these issues.

How 3D Printing Works in Spinal Disc Implant Design

The process of creating a custom spinal disc implant begins with detailed imaging of the patient’s spine using CT or MRI scans. These images are converted into digital 3D models that serve as the blueprint for the implant. Engineers and surgeons collaborate to refine the design, ensuring it meets the specific needs of the patient and the surgical goals.

Once the design is finalized, it is sent to a 3D printer that uses specialized materials, such as medical-grade titanium or biocompatible polymers. The printer constructs the implant layer by layer, achieving a level of precision that is difficult to replicate with traditional manufacturing techniques. After printing, the implant undergoes rigorous testing to verify its strength, durability and compatibility with the patient’s anatomy.

In many cases, 3D printing also allows for the creation of surgical guides. These tools help surgeons position the implant accurately during the procedure, further enhancing surgical precision and outcomes.

Clinical Applications and Success Stories

The use of 3D-printed spinal disc implants has been particularly successful in cases where standard implants fail to meet a patient’s unique needs. For instance, individuals with complex spinal deformities or unusual anatomical variations often benefit from the tailored approach that 3D printing provides.

Studies have shown that patients with custom 3D-printed implants experience significant improvements in pain relief, mobility and overall satisfaction. These implants are particularly effective in reducing complications associated with traditional devices, such as implant migration and hardware failure.

The versatility of 3D printing has also allowed for innovations such as hybrid implants that combine rigid and flexible components. These designs mimic the natural movement of spinal discs, providing a more dynamic and functional solution for patients.

Innovations on the Horizon

The future of 3D printing in spinal care is promising, with ongoing research focused on enhancing the technology’s capabilities. One area of interest is the integration of smart materials into 3D-printed implants. These materials can adapt to changes in the patient’s body, such as temperature or pressure, improving long-term performance.

Another exciting development is the use of bio-printed implants that incorporate living cells. This approach has the potential to create implants that not only restore function but also promote the natural regeneration of spinal tissues. Although still in experimental stages, bio-printed implants represent a groundbreaking advancement in personalized medicine.

Additionally, advancements in imaging and AI-driven design are making it easier to create highly accurate models for 3D printing. These technologies streamline the process, reducing costs and making custom implants more accessible to a broader range of patients.

Dr. Larry Davidson remarks, “A merger of AI and 3D printing could result in the production of an implant that uniquely serves the needs of a specific patient. Such a preparation would be done before a planned procedure based upon the imaging studies of the patient’s spine.” By combining these advancements, surgeons can achieve greater precision, reduce surgical trauma and enhance the overall success rate of spinal procedures.

3D printing has transformed the field of spinal surgery by enabling the design of custom spinal disc implants that align perfectly with a patient’s anatomy. These implants offer numerous benefits, including improved precision, better functionality and reduced risk of complications. While challenges such as cost and regulatory approval remain, the continued evolution of 3D printing technology is addressing these barriers and expanding its potential applications.

As 3D printing continues to advance, its role in spinal care will likely grow, providing patients with more effective and personalized treatment options. By embracing these innovations, surgeons and healthcare providers can offer solutions that enhance quality of life and redefine what is possible in spinal surgery.

Post Comment